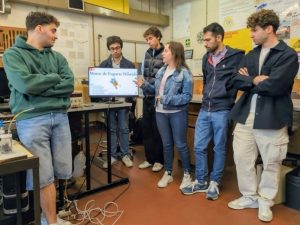

Students from the EEUM Master’s in Mechanical Engineering presented demonstrations of technologies related to clean energy and terrestrial and aerospace propulsion

First-year students specializing in Energy and Environmental Technologies applied the knowledge acquired in the Thermochemical Processes course, building four prototype demonstrators of technologies geared toward sustainability and propulsion. To do so, they used the laboratories of the Department of Mechanical Engineering (DEM), such as the Laboratory of Mobility and Applied Thermodynamics (LaMoTA) — under the responsibility of the course lecturer —, the machining and additive and subtractive manufacturing resources of Lab4DEM, and the technical support of the DEM Educational Workshops.

The projects presented were as follows:

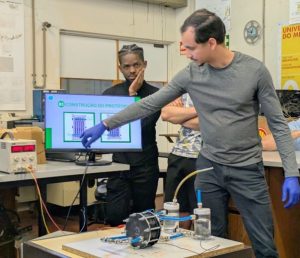

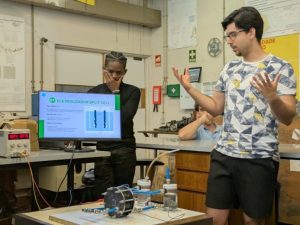

Electrolyser for green hydrogen production

One of the projects focused on developing an electrolyser for the production of ‘green hydrogen’ from water electrolysis. This type of hydrogen is considered ‘green’ because it allows the excess electricity production from intermittent renewable sources, such as wind or solar photovoltaic, to be harnessed in the form of chemical storage. This electricity is used to break down water into hydrogen and oxygen, which can then be used in fuel cells or in combustion processes without greenhouse gas emissions.

The prototype developed represents a significant advance over previous versions, implementing a bipolar configuration, where the electric current flows in series through the various electrodes, allowing the use of higher voltage and lower current sources. The circulation of the electrolyte through the plates was also implemented, similar to a plate heat exchanger, maintaining the split cell configuration, where the hydrogen and oxygen production circuits remain separate.

Biomass gasifier

Another group worked on improving an updraft-type biomass gasifier. This technology converts low-value, high-ash solid fuels — such as forest biomass waste — into combustible gases (syngas, in its purified form). These gases can be used in the production of synthetic fuels as alternatives to fossil fuels or in motor generators for the production of heat and electricity with neutral greenhouse gas emissions.

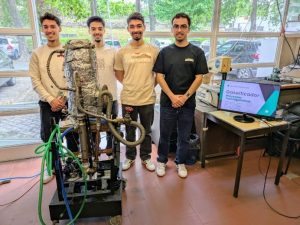

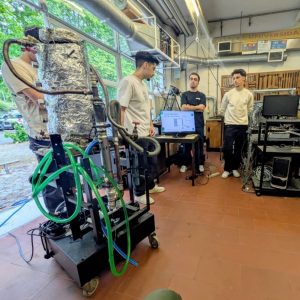

Hybrid rocket engine

A third group developed a hybrid propulsion rocket engine (solid fuel, fluid oxidiser), a technology with the potential to combine the simplicity of solid fuel engines with the control of liquid propulsion engines. In this case, moulded paraffin was used as fuel and compressed oxygen as oxidiser. Although it is a low-pressure combustion chamber prototype for safety reasons, the students managed to achieve ignition. This project also involved the collaboration of students from the Master’s in Aerospace Engineering programme, who are developing work in this area.

Ultra-efficient combustion engine (Shell Eco-Marathon)

The fourth group focused on assembling and upgrading an internal combustion engine that had participated in previous editions of the Shell Eco-Marathon, a competition in which the University of Minho intends to participate again after a few years’ hiatus. The engine incorporates extreme fuel economy strategies, enabling the BebUMlitro vehicle to exceed 1600 km/L and win the award for best Iberian vehicle at the event.

According to Francisco Brito, lecturer responsible for the Thermochemical Processes course unit, this type of project with a practical laboratory component proved to be very stimulating for students, who, in general, achieved very satisfactory results. The lecturer also points out that the pedagogical surveys of this course unit have reflected, over the years, the students’ appreciation for the practical component, which contributes to a better assimilation of the concepts covered in class. He also adds that some of these projects have been continued in master’s theses, being integrated into the lines of research in applied thermodynamics developed at LaMoTA. Finally, he emphasised the important support of several DEM collaborators, in particular Eng. Filipe Marques, from the Pedagogical Workshops, whose contribution was essential to the success of the projects.

The School of Engineering congratulates everyone involved in these projects!